Aircraft Spare Parts Inventory Management - We provide our customers with the highest quality certified engine replacement parts at the most competitive rates; when they need them. Our in-house engineers and planners work with customers to plan for workscopes to control costs.

The Engine Solutions Group at GA Telesis offers a comprehensive one-stop shop for jet engine replacement parts. We maintain one of the world's largest and most complete inventories of commercial jet engine parts and we have disassembled over 600 commercial and regional aircraft engines.

Aircraft Spare Parts Inventory Management

It has been recently revealed that even if an airline invests up to $100-200 million in a spare parts stock it can still be unable to cover every possible malfunction or need. For example, according to a survey carried out by Oliver Wyman consultancy agency, in North America alone airlines spend $110 million on over-insured and poorly positioned spares.

Moreover, there are up to $65 million in spares which are under-insured, while being highly critical to operations. The latter are often subject to long lead times or are in short supply for aircraft-on-ground situations causing many maintenance-related delays and cancellations.

Locatory.com is a part of Avia Solutions Group - a WSE-listed company with more than 17 subsidiaries providing global aviation business solutions covering everything from aircraft maintenance and repair, crew training, technical training to ground handling, crew leasing, and other aviation related services.

GA Telesis is committed to the highest level of C&E support by working with its suppliers and customers across the globe to ensure that all of their parts requirements are met. Our C&E group offers a wide range of programs and services, including:

Storage spare parts for airplanes serves as an insurance against costly downtime. Thus, carriers and their suppliers must try their best to determine the most adequate insurance coverage, i.e. ensure that the right amount of spares is always in the right place and at the right price.

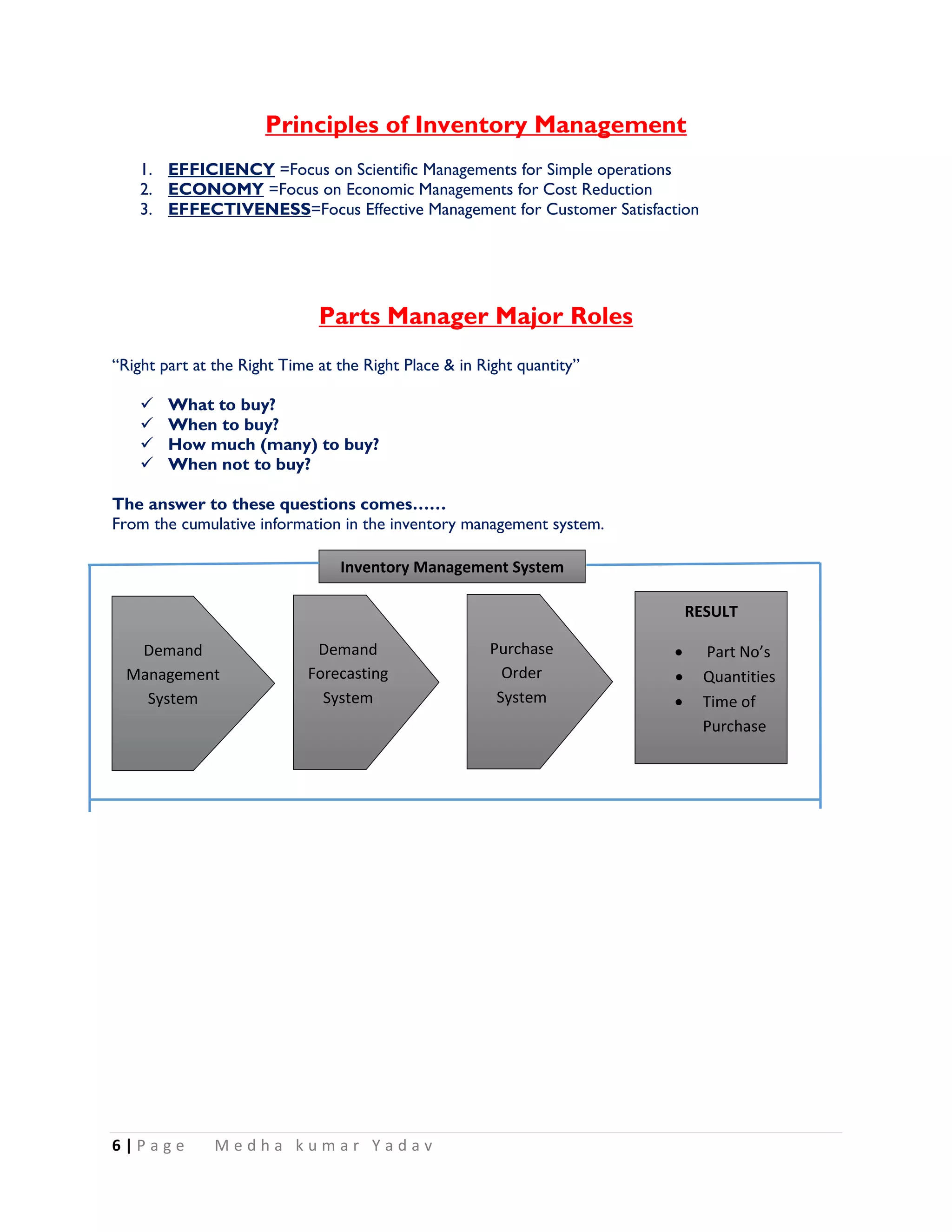

When managing such processes many companies tend to rely on the spare parts lists recommended by OEMs or spares' providers. However, these lists are normally formed whilst taking into consideration the average failure characteristics of particular components and parts or, in the case of a repairable unit, the average repair time only.

Unfortunately, the specialists producing these lists tend to overlook the economic impact to an airline having an aircraft out of service while waiting for a spare part to arrive. According to the CEO of Locatory.com, a good point to start is to prioritize what it is you want to protect and where to focus your energy.

In the case of rare parts, you can establish your own stock by buying available spares on the market and establishing a control team to ensure their reliability and operability. Having a few used aircraft for teardown at your disposal is another option.

Moreover, if there is only one source of supply, an MRO or a carrier may consider investing in or acquiring that supplier to ensure viability: here, even investing in a competitor can be justified. “Airlines must carefully consider the number, type and price of the parts they are the most likely to be in need of, not to mention the place that these parts should be deployed.

Then they must proceed with categorizing the components and spare parts based on how critical they are to the operation and estimate the possible or average costs of downtime. Thus, by streamlining and eliminated redundant inventory management and logistics processes, the internal cycle times can be reduced by more than 50% resulting in considerable financial savings,” shares Zilvinas Sadauskas.

“But there will always be some factors that can complicate the situation and are immune to meticulous planning. For instance, some rotable parts may no longer be manufactured or are too expensive to rebuild. Also, an earthquake or any other natural disaster may simply demolish your stock.”

GA Telesis understands that airlines are constantly looking for new and more effective ways to reduce the cost of doing business. Our Inventory Solutions Group assists airlines in managing inventories in order to lower carrying costs and improve overall spare parts availability.

The internal experts and engineers at GA Telesis work with our global customers to identify the best alternatives where needed and to design custom repair programs. Locatory.com is an IT company supporting the aviation industry with IT-based Supply Chain Optimization solutions worldwide.

The company develops and maintains its own trading platform catered specifically to the aircraft spare parts aftermarket while offering proactive customer support and enhancing the industry with effective supply chain management solutions. GA Telesis appreciates that C&E parts can comprise a significant portion of our customers’ daily requirements.

We know that the smallest bolt or washer can keep your aircraft on the ground just as quickly as an unserviceable engine. GA Telesis treats your C&E requirements with the utmost urgency. All materials in our C&E inventory have undergone our company's rigorous quality control processes and the majority of our inventory is in new surplus condition.

At GA Telesis, our goal is to serve as the one-stop-shop for all of your material needs. Over the past several years, our company has invested substantial resources to increase our on-hand inventory levels of consumable and expendable.

Our Consumable and Expendable Group consists of a dedicated team of professionals that focus solely on the C&E material requirements of our customers. GA Telesis maintains one of the world's largest ready-to-go aircraft parts inventory. Leading airlines around the globe choose GA Telesis because we offer an uncompromising level of quality and reliability.

Our customers know that they can count on us to deliver the right part, to the right place, at the right time. Our industry expert Sales Teams and Product Line Managers at GA Telesis work onsite to develop flexible inventory programs that best meet our customers' needs.

Our proprietary database allows us to analyze and evaluate customers' inventories, turning excess parts and engines into cost savings. “Without any doubt, sometimes planning is difficult, as some repairs are intermittent and variable. Meanwhile, many critical parts and components have long lead times and are expensive.

You have to strike a balance between how many of those items you're going to stock against the risk of not having them. In such cases, joint stocks or e-procurement systems become especially handy, as you don't really have to buy too much, but can rely on a wide network of MROs and operators,” comments Zilvinas Sadauskas, the CEO of Locatory.com

“Despite the fact that commercial aviation heavily relies on the spare parts supply, most commercial airlines and MROs are still managing their supply chain processes ineffectively, which often results in stocking levels of spare parts while, at the same time, experiencing costly delays and downtime,” says Zilvinas Sadauskas, the CEO of Locatory.com.

A conventional inventory management plan is usually based on an implicit assumption that nothing goes wrong in the supply chain. However, it quite often does. For instance, supply chains are as vulnerable to natural disasters as any other areas of aviation business.

In order to prevent or at least minimize the chance of possible malfunctions in a supply chain it might be worth to review the supply chain management procedures from the perspective of an insurance broker once in a while.

Determining the exact spare parts-related needs of a particular carrier and/or MRO provider may not only optimize the speed of relevant processes, but also bring considerable cost savings.

aircraft parts inventory software, aircraft inventory repair, aircraft inventory mgmt, avpro software

![42 Trending Sell Aircraft Spare Parts Businesses [2023] - Starter](https://s3.amazonaws.com/www.starterstory.com/businesses/website_screenshots/000/389/791/original/open-uri20201204-4-1auu8if?1607088794)

://generalaviationnews.com/wp-content/uploads/2016/01/SSP_Foam_Mat-96x125.jpg 96w" sizes="(max-width: 208px) 100vw, 208px" />Bill Nash, CEO of Super Soundproofing, sent me a helpful link to his Soundproofing Aircraft Cabin Booklet. True, Bill sells soundproofing material, but for anyone in the process of building or repairing or annually maintaining an airplane, his booklet is worthy of a read.

://generalaviationnews.com/wp-content/uploads/2016/01/SSP_Foam_Mat-96x125.jpg 96w" sizes="(max-width: 208px) 100vw, 208px" />Bill Nash, CEO of Super Soundproofing, sent me a helpful link to his Soundproofing Aircraft Cabin Booklet. True, Bill sells soundproofing material, but for anyone in the process of building or repairing or annually maintaining an airplane, his booklet is worthy of a read.